Tunnel progressive dryers

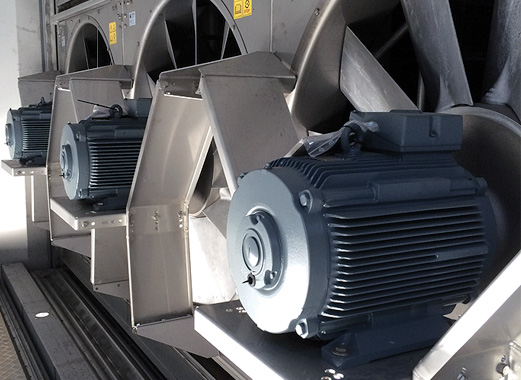

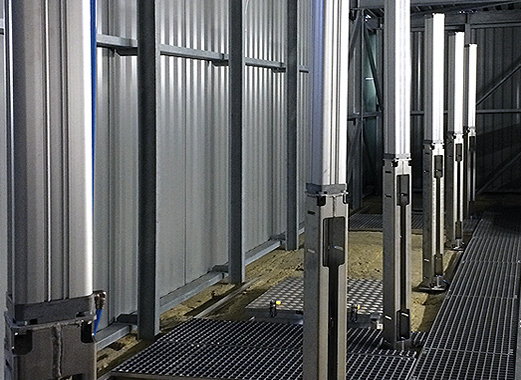

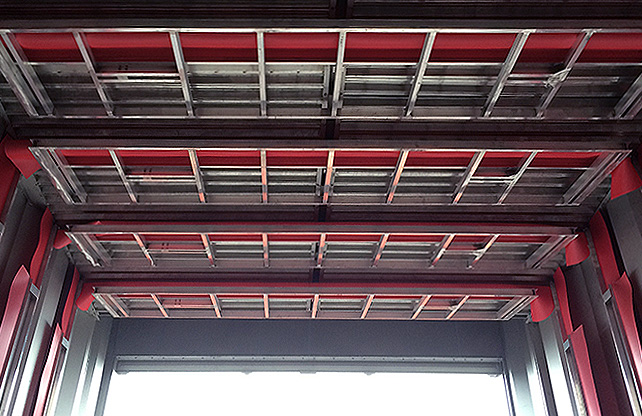

Tunnel progressive dryers are suitable for drying a larger quantity of one type of material, mainly coniferous wood. Effective use is when the need of drying is from 25 000 m3 of wood per year. This is the tunnel drying chamber with a continuous drying process. The timber is placed on trolleys and fed automatically to dryers using a conveyor system, sequentially passes/goes through the drying zones.

Continuously for higher quality

The big advantage of progressive tunnel drying kilns is to provide the same and equal drying conditions for all loaded (dried) material and shortening the total time of drying up to 30% compared to conventional chambers loaded/fed by forklift. Low consumption of electric and heat energy is achieved by using efficient heat recovery units. Each KATRES´s progressive tunnel drying kiln is designed individually according to customer specification so that it was possible to take maximum benefit of the technological advantages of the method of drying in these chambers/kilns.